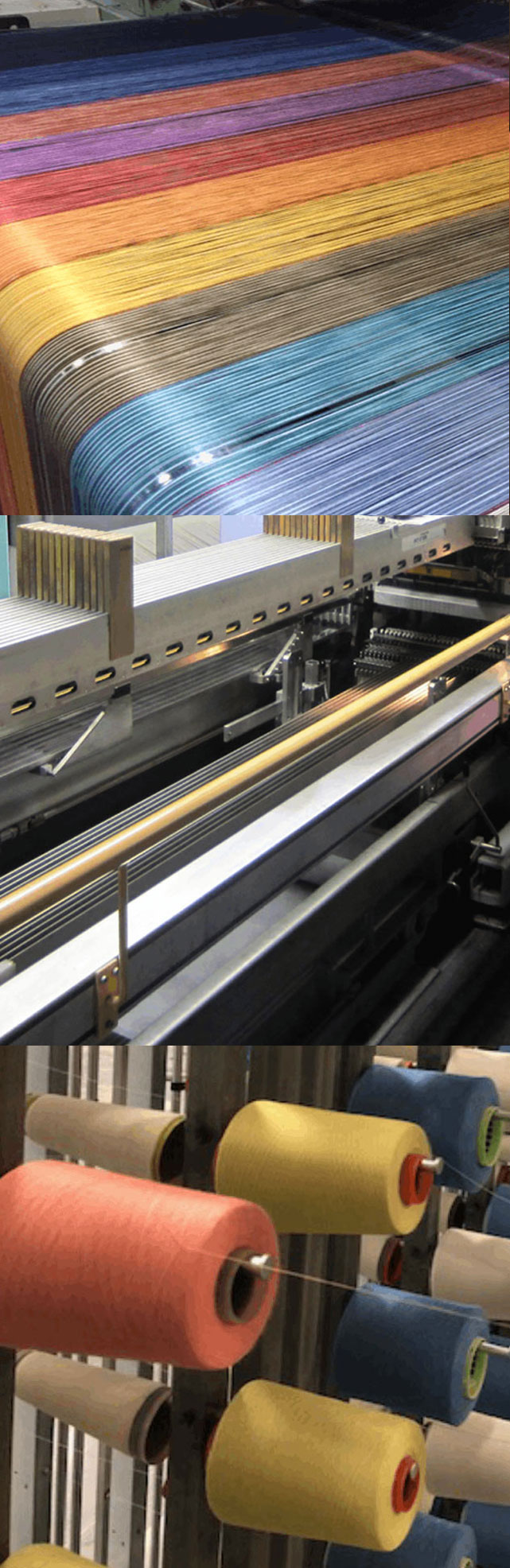

Our Factory

Bower Roebuck have been manufacturing and weaving on the same site since 1899. Investing in the latest modern machinery is inherently connected to our desire to improve quality. Our factory is ideally suited to weaving long and short production runs, combining technology and our highly skilled workface allows us to produce a wide variety of high-quality wool and blended fabrics.